Do you have any knowledge about cold roll forming machine?

1. What is the process of roll forming?

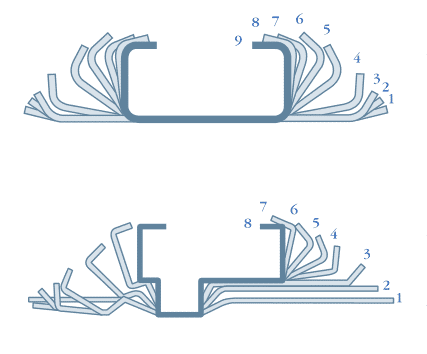

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rollers, each of which makes only incremental changes in the forming. The sum of these small changes in form is a complex profile. In conventional stamping the entire part is formed all at the same time.

2. What is the function of roll forming machine?

Roll forming machines are designed to make sheet metal into straight formed shapes profiles. The roll forming process takes a continuous flat sheet of metal and power feeds it through a successive series of hardened steel rollers, which station by station shape the metal into a finished shape as it passes through them.

3. Design machine as customers’ personal requirements

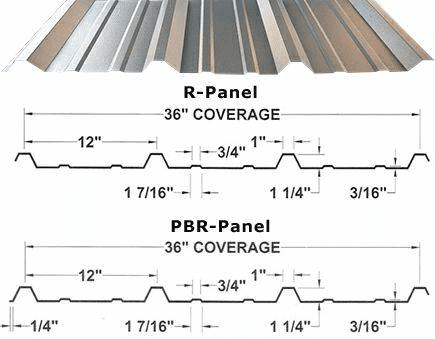

ZTRFM focus on the panel roll forming line manufacturing in the past 30 years, and our metal panel roll former already exported to more than 150 countries. Our machine is customized, we can design machine as customers’ personal requirements. For example we designed R-PANEL, PBR-PANEL, AG-PANEL roll forming lines for the united stations. We designed TR4 TR5 panel roll fomer for Peru. We designed PV4 PV6 panel roll forming lines for Chile. In sum we have full experience for the machines designing and manufacturing.

4. You can choose as your requirement

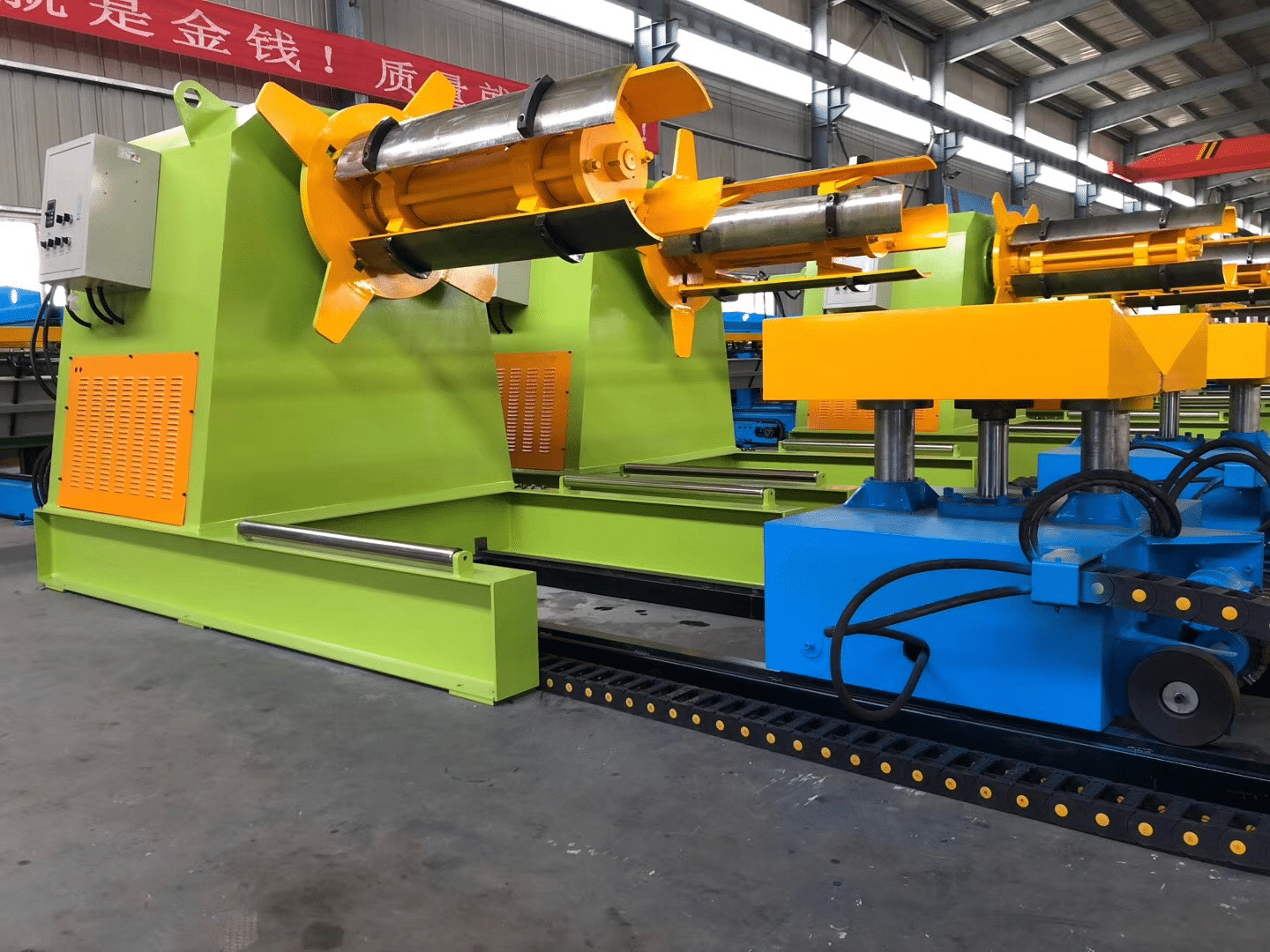

We can give you different options for the decoiler and collect table of the panel roll forming line. For example, for the decoiler we have manual decoiler and hydraulic decoiler, and for the hydraulic we have different options for the loading capacity, we have 5t 8t 10t 15t. And for the collect table we also give you different option for the length and automatic type or manual type.