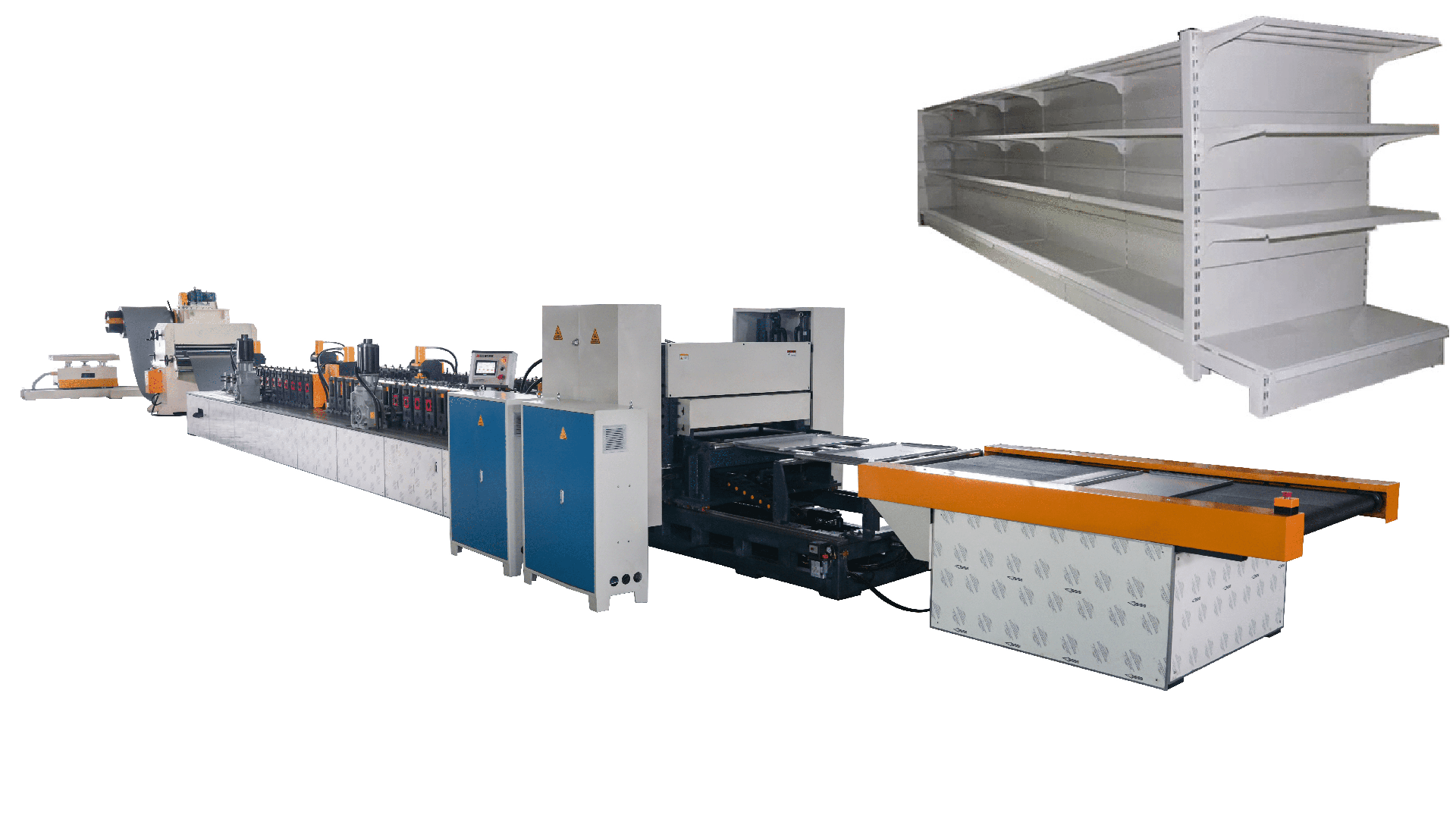

The ZTRFM Supermarket Storage Rack Panel Roll Forming Machine is a versatile solution for cold roll forming of a wide array of shelf profiles, including storage shelves, supermarket displays, and heavy-duty racking systems. This integrated marvel seamlessly combines multiple production steps into a single machine, revolutionizing efficiency and productivity.

The ZTRFM Supermarket Storage Rack Panel Roll Forming Machine is a versatile solution for cold roll forming of a wide array of shelf profiles, including storage shelves, supermarket displays, and heavy-duty racking systems. This integrated marvel seamlessly combines multiple production steps into a single machine, revolutionizing efficiency and productivity.

Powered by advanced numerical control technology, our metal shelf rack panel forming machine ensures precision control over the dimensions and contours of shelf laminates, delivering unparalleled accuracy and consistency.

Cost-effective, eco-friendly, and high-efficiency – the shelf panel equipment offers a compelling combination that caters to diverse production requirements. By automating production processes and minimizing labor intensity, it equips enterprises with a competitive edge in today's fiercely competitive markets.

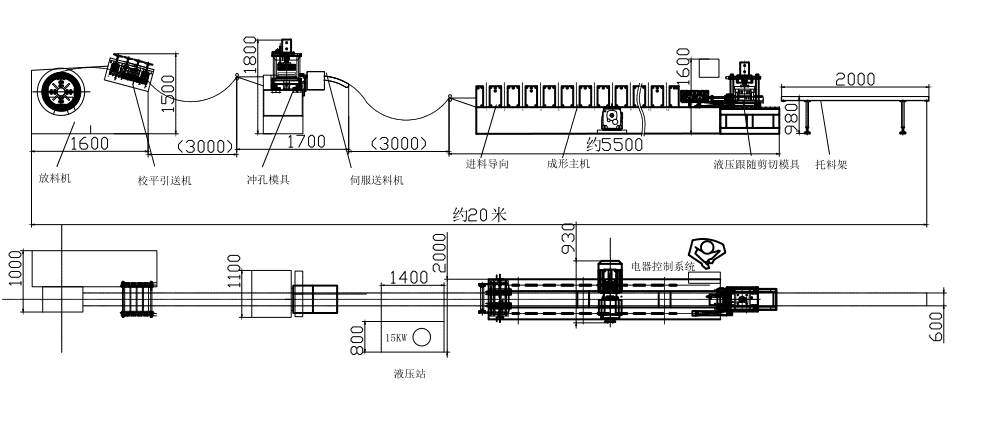

Comprising essential components such as discharging, leveling, feeding, punching, precision forming, fixed-length cutting, a receiving platform, and an electric control box featuring PLC technology, the ZTRFM shelf equipment is a comprehensive solution designed to streamline operations and maximize output.

Shelf Panel Making Machine Production Process

Decoiler - leveling - servo feeding - punching system - bilateral roller rolling forming - hydraulic automatic cutting and bending - receiving table - automatic welding

ZTRFM Unique Design

1. This shelves panel automatic production line can produce different specifications of the board, integrates the numerical control to complete the punching, shearing, cold roll forming and folding process, greatly saving labor and improving work efficiency, replacing the traditional CNC punching machine, CNC bending machine, CNC shearing machine Combined function.

2. Different specifications are completed by numerical control. Punching different holes, you can choose to complete the stamping die. The roller press is adjustable by a combination of two machines.

ZTRFM Shelving Equipment Features

1.The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient.

2.The forming frame is welded using high strength channel steel. High strength and long service life.

3.The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

4.The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C.

5.The transmission structure is gearbox transmission or chain transmission.

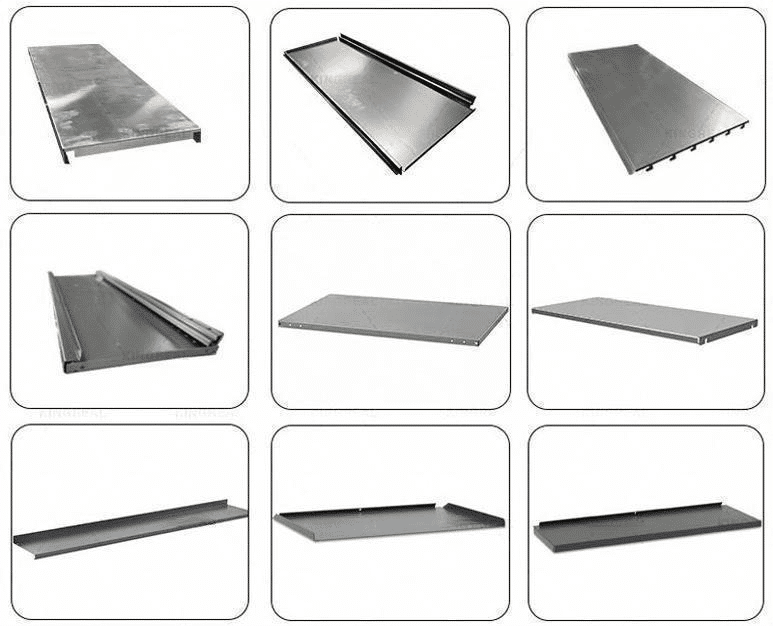

Final Product Display

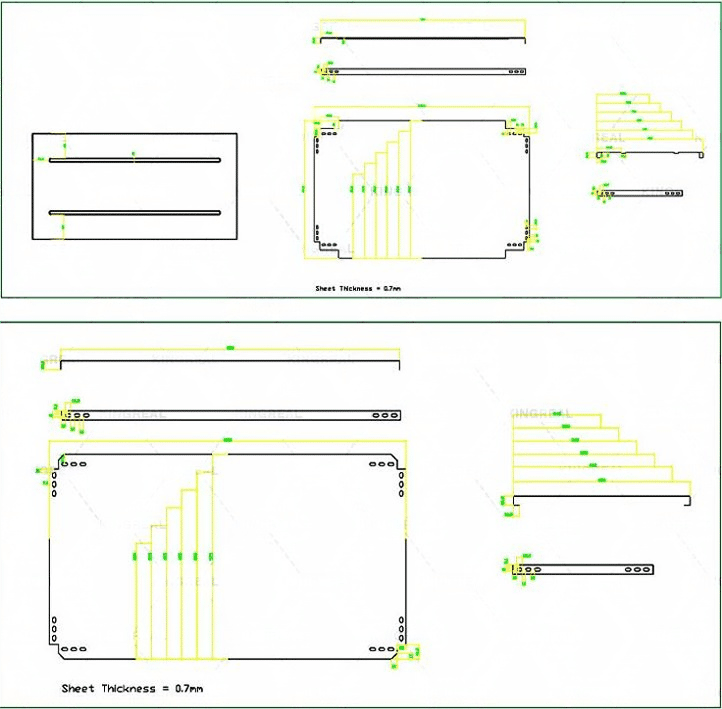

Reference drawings of different metal shelf