High-speed guardrails, also known as highway guardrails or road crash barriers, are vital safety facilities on highways. They are usually installed on both sides of the road, in median strips, or at specific hazardous road sections. Their purpose is to prevent vehicles from veering off the road, to mitigate the severity of traffic accidents, to safeguard the lives of passengers, and to maintain normal traffic order on the highway.

The terms "crash barrier" and "2-rib/3-rib guardrail" are commonly used to refer to this heavy-duty cross-sectional profile in highway systems. Globally, these crash barriers are manufactured using roll forming machines, adhering to nearly identical and standardized patterns. While some countries specify a minimum thickness of 3mm, others accept profiles as thin as 2mm. According to international highway standards, both sides of high-speed highways should be equipped with crash barriers. The W-beam guardrail, specifically, is widely utilized in roadway systems. It is a cold-rolled product that transforms steel coils into either a two-wave or three-wave guardrail shape. Crash barriers on highways have proven exceptionally effective in decreasing both the number and severity of accidents. There is our highway guardrail roll forming machine.

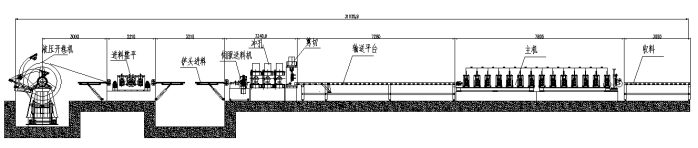

Process flow

Automatic unloading rack—leveling feeding—servo feeding—hydraulic punching and cutting—fast feeding table—forming host—automatic-palletizer

Technical of the whole line

Part 1 5 tons hydraulic decoiler

1.Capacity: 5 tons

2.Coil diameter:φ450-φ530mm/φ630mm adjustable

3.Coil width:max 800mm

4.Hydraulic power:3kw

5.Motor power:5.5kw

6. Decoiler spindle diameter: φ190mm

7. Tensioning cylinder diameter: φ200mm

8. Electrical control system: inverter and other main electrical components adopt well-known brands

Part 2 Guiding & leveling device

1.Placed on the machine by seller

2.Leveling rollerr: 9pcs,add 2 pairs of feeding rollers

3.Roller diameter:120mm

4.Material:40 CR, Heat treatment HRC48°~52°

5. The leveler is equipped with guide rollers at the front and rear, and two groups of 4 rollers on the left and right to control the up and down and left and right jumping of the belt material. The feed port is equipped with a pressing device

6. Leveling machine motor power 11KW, frequency conversion speed regulation, ZQ350 reducer, speed ratio (i=20.49), leveling speed 10-25M/min

7. Leveling feed width range 300-800mm.

6.It can be the conveyor and the leveling rolls greatly improve the flatness of the panel,and the space between the rolls can be adjusted according to the different panel thickness

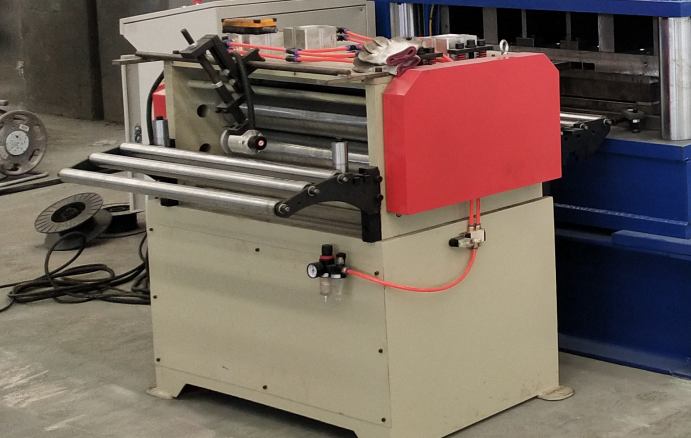

Part 3 Servo Feeder

1. Motor power 4KW + planetary reducer reducer

2. Speed ratio 1:10

3. Feed roller diameter ¢120mm

Material is 40Cr, heat treatment HRC48º~52º

Part 4 Hydraulic pre-punching and cutting device

1.Type:Hydraulic

2.Punch mode:Four pillars hydraulic powered punching system

3.Motor power:45kw

4.Punching mold material: Cr12 Mov with quenched treatment,hardness HRC58-62°

5.Blade material: Cr12 Mov with quenched treatment,hardness HRC58-62°

6.Use a four-column hydraulic punching machine, the equipment is equipped with a set of punching and cutting dies, the hole type can be selected according to needs, the punching die is universal for nine and ten holes, and it is also equipped with a set of middle reinforcement hole punching mechanism.

7. Cylinder diameter ¢250mm, ¢120mm stroke 30mm, four-column structure, machine base is made of steel plate welded and aged.

8. 3 sets of rolling forming dies in the front. Material: GCr15, overall quenching, hardness: HRC58~62º

Part 5 Fast feeding platform

1. Usage: After the plate is cut, it is quickly fed into the main machine.

2. The motor power:2.2KW, 4-pole ordinary motor, ZQ250 reducer, speed ratio 31.5;

the feed roller diameter:¢120mm, the material is 40Cr, and the heat treatment HRC48º~52º

Part 6 Main forming machine

1.Rolling shaft material:45# steel with quenched treatment

2.Shaft diameter:110mm 40CR

3.Roller material:GB-Cr15 with heat treatment

4.Rolling station:17 stations

5.Working speed:18-20m/min

6.Machine frame:Iron cast vertical structure

7.Machine body:400# H steel welded

8.Bearing:Chinese famous brand HRB

9.Work power:2*22kw

10.Transmission:By gearbox

11.Appearance:Good appearance with no burrs in steel body nor traces of rust or defects in painting.

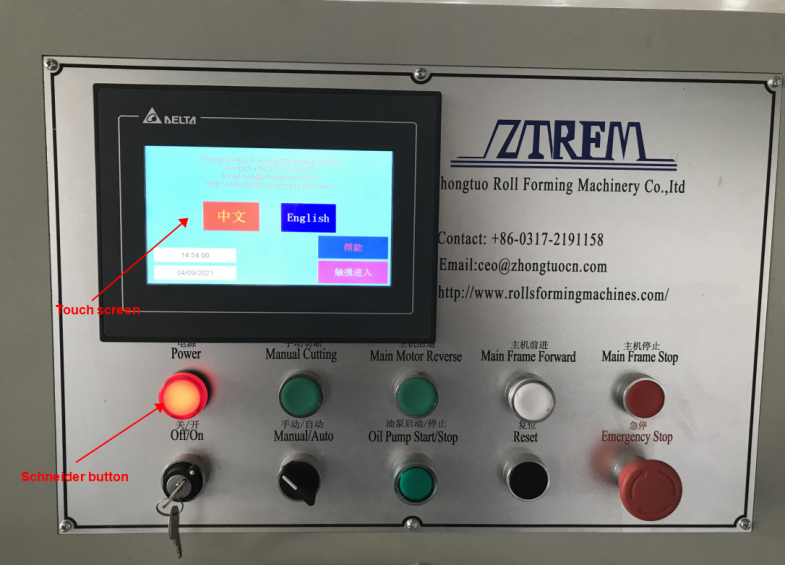

Part 7 Control system

1.PLC control the product length and quantity

2.Screen:touch screen

3.Language:Chinese and English (Or as customer’s request)

4.Encoder:Omron

5.This system mainly consists of PLC,frequency converter,and operation platform,all the electronic adopt the famous brand,which can guarantee the quality and lifetime.And there is a breakdown protect device,ad if there is any fault of the control switch,the whole production line will stop working automatically.

6. Brand: Siemens

Part 8 Automatic Stacker

1. Square tube welding, equipped with roller sliding

2. 4-meter lifting and stacking

3. Lifting servo motor 3KW

4. Horizontal servo motor 1.5KW

5.Cylinder swing blanking