Eaves Flashing Making Machine – High-Quality Drip Edge Production

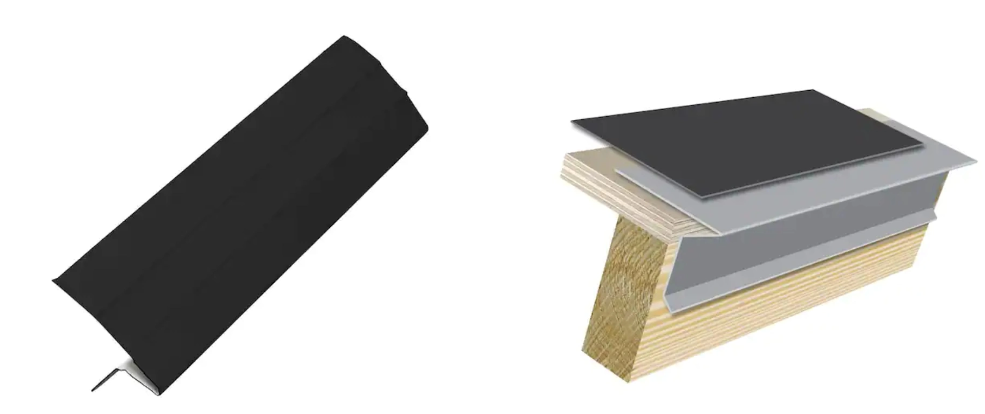

The Eaves Flashing Making Machine is an essential tool for producing roof eave drip edges, a key component in any roofing system. These metal strips are installed along the edges of the roof to prevent water from seeping into the underlying structure. This machine is designed for efficient, precise, and high-quality production of drip edges, ensuring that your roofing projects are watertight and durable.

What is Eaves Flashing and Why is it Important?

Eaves flashing, also known as drip edge, is a critical part of a roofing system. It prevents water from damaging the roof structure by guiding rainwater away from the roof and into the gutter. Without proper eaves flashing, water can seep into the structure, leading to potential damage and costly repairs.

Features and Benefits of the Eaves Flashing Making Machine

The Eaves Flashing Making Machine uses advanced technology to produce drip edges with high precision and efficiency. The machine is equipped with adjustable rollers and bending mechanisms, allowing for the creation of customized drip edges that fit the specific needs of any roofing project. Here are some key features of the machine:

Advanced Technology:

The machine is equipped with adjustable rollers and bending mechanisms, enabling it to accommodate different sizes and profiles of drip edges. This flexibility ensures that the machine can produce customized, high-quality drip edges for various roofing applications.

Automatic Uncoiler:

The automatic uncoiler comes with two coil holders, each capable of carrying 1.5 tons of material. It is powered by a 0.75 KW motor to rotate the rolls and a 3 KW motor to ensure tensioning. This setup ensures smooth and efficient feeding of the material into the forming machine.

Max feeding speed: Up to 100 meters per minute.

Roll Forming System:

The machine’s frame is made of cast iron stands, processed with CNC tools to ensure stability and precision.

Shafts are made from 45# steel, and undergo quenching and tempering heat treatments for enhanced durability and resistance to deformation during long-term use.

Rollers are made of high-grade Cr12 alloy steel, CNC-machined for high precision, and high-frequency quenched with HRC 58-62 hardness for long-lasting performance.

Rugging speed: Up to 65-80 meters per minute.

Flying Shear with Servo Motor:

The flying shear is controlled by a servo motor system, guaranteeing fast cutting and high-precision length cuts.

Electric Cabinet:

The electric cabinet uses internationally renowned brands such as Siemens, Mitsubishi, Delta, and Panasonic for PLC and inverters, ensuring reliable performance and longevity.

Schneider components are used for lower power functions, while the OMRON encoder ensures precise operation.

Aviation plugs are used for wiring, making installation simpler and more efficient.

Customization Options:

The machine can be customized to suit specific requirements, whether it’s for different profiles, materials, or production speeds. This makes it a versatile solution for a variety of roofing projects.

Why Choose Zhongtuo’s Eaves Flashing Making Machine?

Precision and Efficiency: The machine is designed to deliver high-precision drip edges with a fast production speed, ensuring your projects are completed on time.

Cost-Effective: By automating the production process, the machine helps reduce labor costs and material waste, making it a cost-effective solution for roofing businesses.

Durability and Reliability: Built with high-quality materials and advanced technology, the machine is durable and reliable, capable of producing consistent results over long periods of operation.

Easy Installation: The machine is designed for easy installation, with clearly marked wires and convenient aviation plugs for quicker setup.

Applications of Eaves Flashing

The Eaves Flashing Making Machine is ideal for producing high-quality drip edges used in various roofing systems. These drip edges are primarily used in residential, commercial, and industrial roofing projects to provide a clean, waterproof finish along the eaves of the roof.

Contact Us for More Information

For more details on the Eaves Flashing Making Machine or other roofing solutions, contact Zhongtuo Machinery. We offer high-quality, efficient, and customizable roll forming machines designed to meet the specific needs of your roofing projects.