R Panel Roll Former Machine – High-Quality Metal Siding & Roofing Panel Production

As the name suggests, the R Panel Roll Former is specifically designed to produce R panels, a widely used type of metal siding and roofing panel, particularly in commercial steel frame buildings. These panels offer outstanding durability, high wind resistance, and long-lasting performance compared to traditional roofing materials. ZTRFM ensures strict quality control throughout the manufacturing process, offering high-quality R panel roll forming machines with various specifications at competitive prices.

Why Choose R Panel Roll Forming Machines?

R Panel Roll Formers are ideal for producing 36” R panels, which are commonly used in pre-engineered metal buildings. These panels are versatile and can be used for both walls and roofs in commercial and industrial applications. The R Panel metal roofing panels provide exceptional durability, resistance to extreme weather conditions, and require minimal maintenance over their long lifespan.

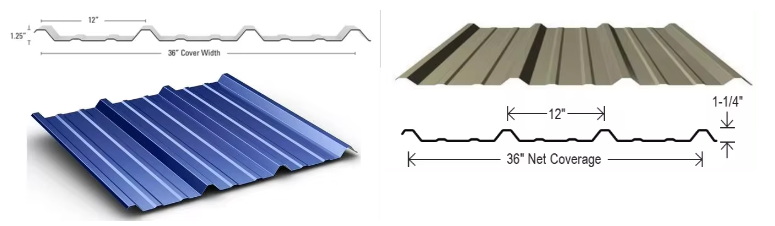

Here is one drawing profile and finished product:

R Panel Roll Former Features

Product Specifications:

· Coil Capacity: 5 tons

· Coil Inner Diameter: 450-550mm

· Feeding Width: Maximum 1220mm

· Structure: Welded steel plates and profiled bars

· Manual Decoiler: For free coil handling

Feeding Device:

· Adjustable Hand Wheels: Located on both sides for precise feeding width adjustments.

· Stainless Steel Rollers: Four rollers ensure smooth entry of the material into the machine and prevent scratches on the material surface.

· Smooth Material Feeding: Three rows of orange plastic rollers help the steel coil enter the machine smoothly.

Roll Forming and Transmission Device:

· Durable Chrome-Plated Rollers: Thick, chrome-plated rollers with excellent hardness for long service life.

· Stable Roller Fixing: Each roller has a unique number and keynotes, ensuring stable attachment to the shaft.

· Transmission System: Uses a gear and double chain for stable, reliable operation.

Hydraulic Cutting Device:

· Four Pillar Cutting System: Ensures stable and precise cutting performance.

Advanced PLC Control System

· PLC Brand: Delta (Taiwan)

· Encoder Brand: Omron

· Electrical Components: Schneider

· Touch Screen Control: Easy-to-use interface available in English and Chinese (or other languages upon request). The system allows users to easily set the order, product length, and quantity.

· Aviation Plugs: Simplifies installation when the machine arrives at your location.

Hydraulic Station

· Hydraulic Motor Power: 5.5 KW

· Hydraulic Oil: 46# hydraulic oil

· Main Components: Includes a hydraulic tank, hydraulic oil pump, two hydraulic pipes, and an electromagnetism valve.

R Panel Roll Former Benefits

· High Durability: Ideal for creating strong, long-lasting metal panels with minimal maintenance.

· Energy Efficient: The use of hydraulic systems and efficient control mechanisms ensures lower energy consumption.

· User-Friendly Operation: Simple setup and operation with PLC control, touch screen, and easy-to-install components.

· Versatile Application: Perfect for both roofing and wall panels in commercial, industrial, and pre-engineered metal buildings.