The Advantage Of Hydraulic Decoiler

Hydraulic decoiler is suitable for higher speed of the roofing sheet roll forming machine.To start and stop working controlled by motor reducer.Loading Capacity about 5-15 tons.It can carry more weight than manual decoiler.Therefore, the hydraulic decoiler is more labor-intensive and save labor than the manual decoiler.

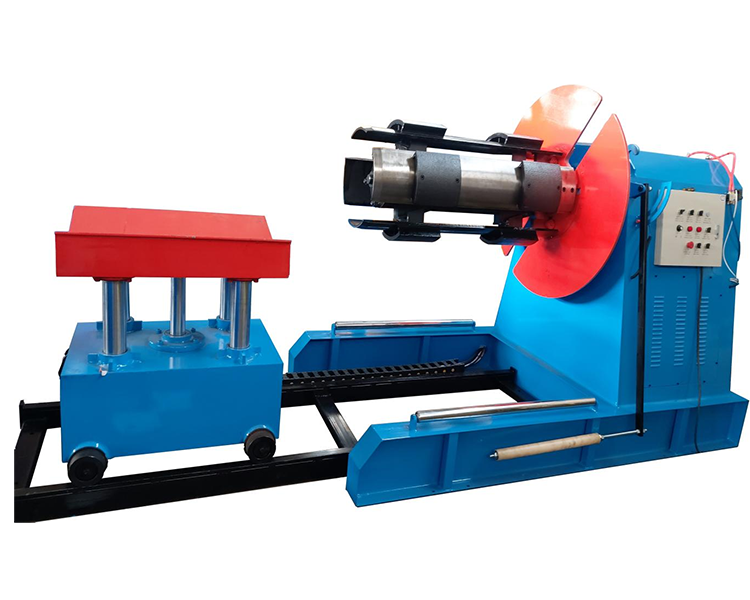

There are many special features in the design of hydraulic decoiler of the tile roll forming machine .Such as rotary arm design is convenient for loading and unloading steel coils, which can be easily operated and used by one person.The core tension is driven by hydraulic pressure, and the hydraulic system is provided with a pressure maintaining device, so that the core tension can not be relaxed after the motor of the hydraulic station stops. The hydraulic motor provides power to actively decoil and discharge materials, which can automatically stop and start according to the running speed of the main forming part, and the stepless variable speed motor can also adjust the output speed of the motor at any time.And the working speed of decoiler is adjustable.There also has stainless steel baffle of the hydraulic decoiler, which is used to prevent the direct contact between the coil and the machine in order to protect the machine. And the baffle is provided with a groove, so that when the steel coil is hoisted by a sling, it can be conveniently accessed.In addition,dovetail groove type diameter adjustment mode of the decoiler is more stable and has better bearing capacity.

The hydraulic decoiler of the roof forming machine produced by GEIT has advantages over other factories.Firstly,It’s easy to load.Secondly,the automated equipment requires only one worker to complete.And also can carry 10~15 capacity.