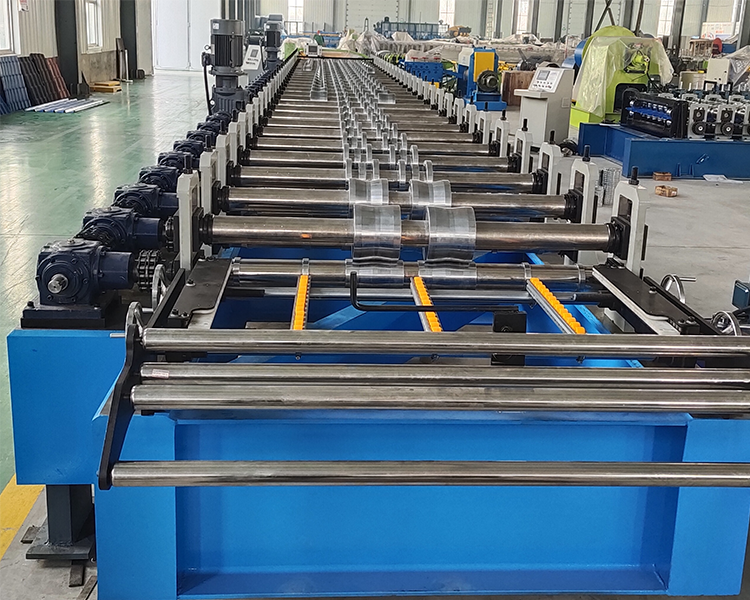

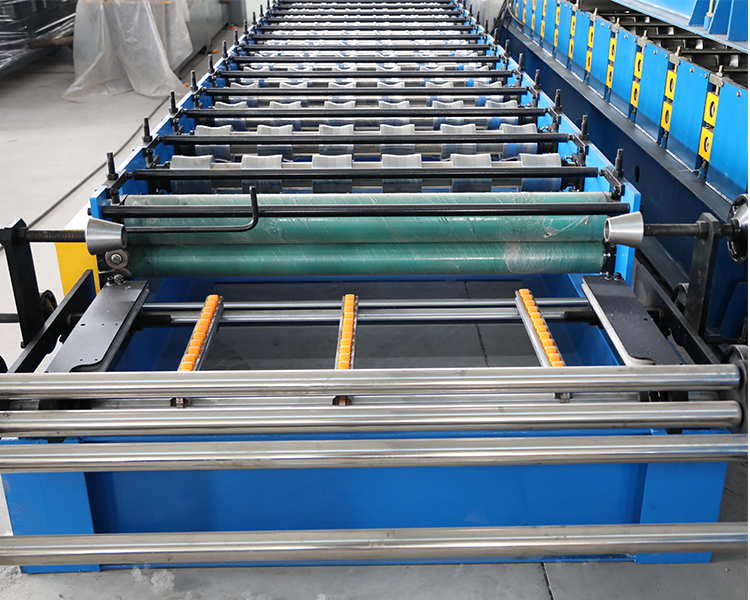

Forming Type of the main forming machine

The main roll forming system is the main forming part of the metal roofing sheet roll forming machine. it can also be designed according to your drawings as you want.

There are two kinds of main forming system of glazed roofing tile roll forming machine produced by our company, one is integral forming, and the other is split forming. If your company covers a large area, you can choose to split forming, because the product produced is more accurate. Without it, the main forming system will not work About the split forming type machine,roller stations will be more than 20 rollers, so this type need a larger space, also it will cost much more than integral forming type machine. But the product after split forming is much better than integral forming. More flatter and more beautiful.About the integral forming type machine, roller stations will be 14-16 rows. Generally, it is little than split forming type. So that the integral type will save the space and the price is lower than split forming type.

![]()

Glazed tile roofing sheet machine production process is the raw materials are put into the drum of the decoiler through the loading car, and enter the main forming system from the guide feed device. There are hand wheel on both sides of the feed port on the main forming machine, and the feeding width can be adjusted to make the raw materials more flat.When the raw material enters the molding stage, the PLC process issues the cutting instruction, the glazed tile comes out, and the work task of the main forming system is over.