Scientific and technological innovation

Roll forming machine

Focus on research and development

05-302025

Maximize Efficiency with Our Advanced PU Sandwich Panel Rolling Forming Machine

05-302025

Maximize Efficiency with Our Advanced PU Sandwich Panel Rolling Forming Machine

Looking to improve your insulated panel production? Our PU s···

05-232025

Why Choose Our High-Speed Stud and Track Rolling Forming Machine?

05-232025

Why Choose Our High-Speed Stud and Track Rolling Forming Machine?

Why Choose Our High-Speed Stud and Track Rolling Forming Mac···

05-202025

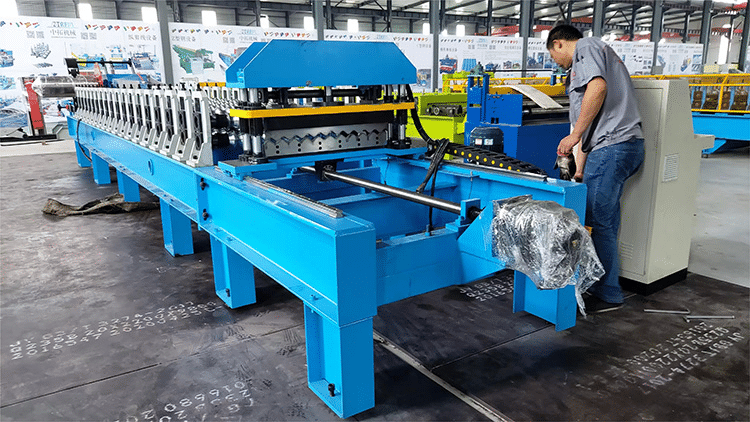

Double Layer Roll Forming Machine for South Korea

05-202025

Double Layer Roll Forming Machine for South Korea

The double layer roll forming machine is engineered to deliv···

05-162025

Zhongtuo's Roll Forming Machines Make a Breakthrough in Turkey

05-162025

Zhongtuo's Roll Forming Machines Make a Breakthrough in Turkey

Xu Lianxing, the chairman of Cangzhou Zhongtuo Cold Roll For···

05-132025

Upright Rack Profile Making Machine: High-Efficiency Solution for Industrial Storage Systems

05-132025

Upright Rack Profile Making Machine: High-Efficiency Solution for Industrial Storage Systems

The Upright Rack Profile Making Machine is a specialized rol···

05-092025

Cangzhou Zhongtuo : Leading Manufacturer of Cold Roll Forming Machines

05-092025

Cangzhou Zhongtuo : Leading Manufacturer of Cold Roll Forming Machines

Cangzhou Zhongtuo Cold Roll Forming Machinery Co.,···

Contact us

General Industry Tech Hebei Developing Co., Ltd.

Address:N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Phone/Whatsapp:+86 13091162987

E-mail:web@geitgroup.com

Phone:+86 13091162987